三.Plate Sulfation Phenomenon and Reasons

Plate sulfation Phenomenon means the formation of white and hard lead sulfate crystals on the plate, which is very difficult to convert into active substances during charging.There are the following phenomena after sulfation of lead-acid battery plates.

1.The voltage of lead-acid battery rises rapidly during the charging process, and its initial and final voltage is too high, and the final charging voltage can reach about 2.90V/single cell.

2.During the discharge process, the voltage decreases rapidly, that means: it drops to the termination voltage prematurely, so its capacity is significantly lower than that of other batteries.

3.During charging, the temperature of the electrolyte rises rapidly and easily exceeds 45°C.

4.During charging, the electrolyte density is lower than the normal value, and air bubbles occur prematurely during charging.

5.When the battery is dissected, it can be found that the color and state of the plates are abnormal. The positive plate is light brown (normally dark brown), the surface of the plate has white lead sulfate spots, and the negative plate is gray-white (normally gray).The surface of the plate is rough, it feels like grit to the touch, and the plate is hard.

6.Severe sulfation, the lead sulfate white crystals formed by the polar plate are coarse and cannot be restored to active substances under normal circumstances.

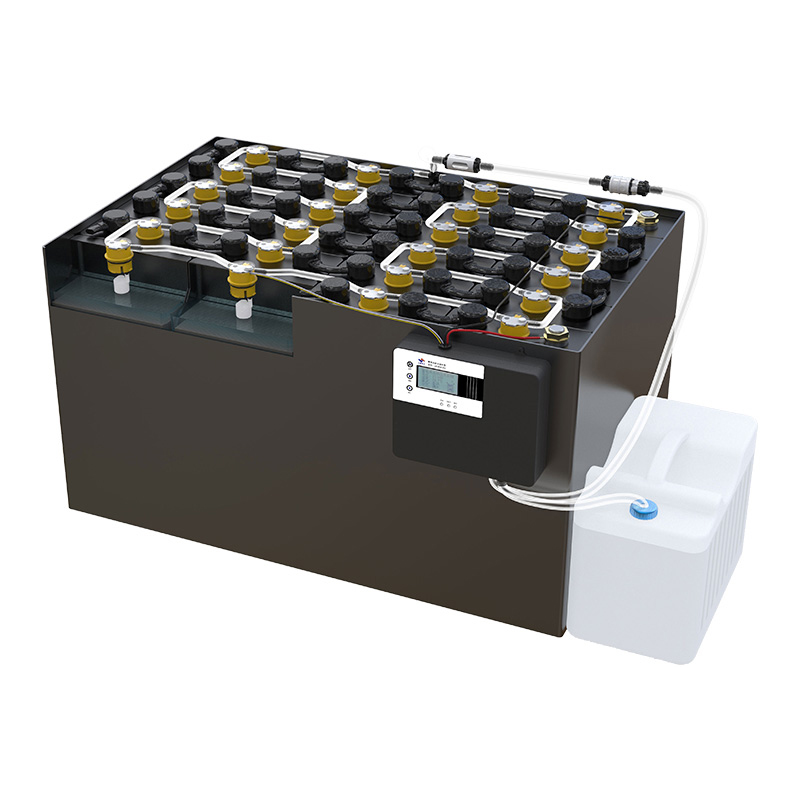

(How to maintain electric forklift battery? You can try Battery Watering Gun or Battery Watering System)

四.The main reasons that cause plate sulfation are as follows:

1.The lead-acid battery is insufficiently charged at the beginning or the initial charge is interrupted for a long time.

2.Lead-acid batteries are not sufficiently charged for a long time.

3.Failed to charge in time after discharge.

4.Frequently overdischarge or small current deep discharge.

5.If the density of the electrolyte or the temperature is too high, lead sulfate will be deeply formed and difficult to recover.

6.Lead-acid batteries have been shelved for a long time and have not been used for a long time without regular charging

7.The local action of the internal short circuit or the water on the battery surface causes leakage.

8.The electrolyte is impure and self-discharge is large.

9.The electrolyte level inside the battery is low, so that the exposed part of the plate is sulfated.

(How to add water for electric forklift battery? Battery watering system is your first choice.)

In the case of normal use of lead-acid battery, most of the active materials (Pb02 and Pb) on the positive and negative plates are converted into small-grained lead sulfate. These soft and small-grained lead sulfate are evenly distributed in the porous structure. On the active material, it is easy to contact with the electrolyte and restore to the original material PbO2 and Pb during charging.

Due to the above-mentioned improper use, the active material on the electrode plate will gradually form lead sulfate with coarse crystal grains. The pores hinder the penetration and diffusion of the electrolyte and increase the internal resistance of the battery. At the same time, when charging, this coarse and hard lead sulfate is not as easy to convert into PbO2 and Pb as the soft and small-grained lead sulfate.

If it lasts too long, these coarse and hard lead sulfates will lose their reversible effect, resulting in the reduction of the effective material of the plate, the reduction of the discharge capacity, and the shortened service life.