Although the price of electric forklifts is higher than that of internal combustion forklifts, the energy consumption cost of electric forklifts is less than half of that of internal combustion forklifts during their service life. Now that the labor cost is increasing, electric forklifts are more and more favored by the majority of business owners.

Although many business owners choose electric forklifts, they lack sufficient awareness of the maintenance required for batteries. Even know nothing about the maintenance of lead-acid batteries watering, which results in a dramatic reduction in battery life, and an average loss of battery value exceeding 40% of the battery’s own value.

Why does battery need water:

1.When the battery is charging, especially near the gasification stage (Cassing Condition), the electrical reaction is that the water in the battery liquid is electrolyzed. It overflows with hydrogen (H) and oxygen (O) gas, thereby reducing the battery fluid capacity and increasing the concentration.

2.The above reaction also occurs when the battery is discharged, but it is not as strong as when it is charged, but when the battery is continuously discharged at a large current, the above reaction is also quite strong.

3.In the fierce electrochemical reaction, if the level of the electrolyte is too high, the discharged gas will splash and overflow with the battery liquid, which will lead the liquid level of the battery to drop (wherein the sulfuric acid H2SO4 in the battery liquid will lose with the overflow of the battery liquid). If the liquid level is maintained with supplementary pure water, the liquid level of the battery liquid will change (the specific gravity of the battery liquid will be insufficient).

Due to the different situations of splashing and overflowing of battery fluid in each unit, the specific gravity of each unit battery is inconsistent after replenishing water in this way,which results in a potential difference between each unit battery, thereby affecting the performance of the battery. So try to avoid this situation when using the battery.

How to add water to your forklift battery correctly?

Firstly, confirm whether your battery needs water: Generally, the liquid level of the battery must be more than 10mm higher than the lead grid. If the liquid level is lower than this level, it can be considered that the battery is in a state of water shortage, and distilled water or deionized water must be replenished in time.

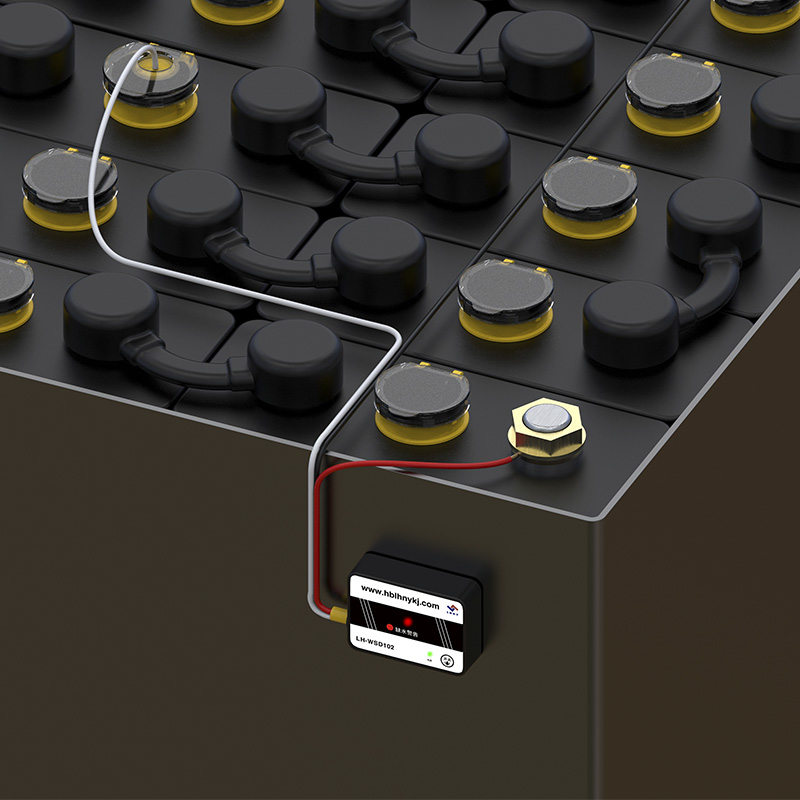

In daily work, the detection of the battery liquid level of the forklift truck is easily neglected by the front-line operators. You’d better equip a battery liquid level indicator to help the driver to confirm the battery liquid level in time.

Then, to replenish water to the water-deficient battery cell

A set of 48-volt forklift batteries has 24 cells. Distilled or deionized water needs to be added one by one. When adding water, please wear the protective equipment (goggles, rubber gloves, etc. to prevent acid burns and corrosion), and the water level should be as high as possible.Or it will affect the balance of battery characteristics and reduce battery life.

Here you can use professional water adding tools, such as battery watering gun, you can easily add water with the gun, which is safe and convenient, and can also help to control the liquid level, ensure the balance of battery characteristics, and prolong battery life.

-1024x731.jpg)

Well-maintained batteries can work 4-5 years. If not, maybe 2-3years, which will lead to a huge loss. We should pay more attention to the maintenance.