An essential part of forklift battery maintenance is to replenish the battery with distilled water or deionized water regularly. During the charging, discharging and storage process of the battery, part of the water will evaporate due to the use environment and internal high-temperature reaction. If the battery is not filled with water in time, the battery will be in a state of water shortage for a long time, which will affect the battery’s service life. So, how should we add water to the forklift battery? When to add? How to add? How much is more appropriate? The following is a detailed introduction for everyone!

During the use of the battery, it is necessary to regularly check the water shortage status of the battery according to the use environment and temperature, and replenish water for the battery in time.

If the battery liquid level is lower than the minimum liquid level, it is necessary to add deionized water or distilled water to between the maximum and minimum liquid levels, and it is strictly forbidden to add battery liquid or tap water. The original battery liquid will dilute or increase the original specific gravity of the electrolyte, causing the performance of the battery to decline. Excessive impurities in tap water will cause the battery to react weakly. Adding tap water for a long time may cause a short circuit and damage the battery.

Forklift Battery Water Filling Time

It is not recommended to add water when the battery is in use. Water should be added at the end of charging (one hour before the end of charging). When charging, the internal bubbles of the battery are churning and the reaction is violent. to a balanced effect.

Principles of adding water to forklift batteries

A small amount for many times, it is strictly forbidden to add too much water beyond the maximum liquid level. If too much water is added, the forklift battery may overflow during charging and moving, resulting in a decrease in the overall specific gravity of the battery, a decrease in performance, water in the tank, and corrosion, and may even cause a short circuit in severe cases.

Before using the forklift battery, the user should carefully read the battery manual and the warning label on the battery box, and try to add water to the forklift battery according to this standard, which is helpful for efficient use and correct maintenance of the battery, and prolongs the service life of the battery.

How To Add Water To Forklift Battery

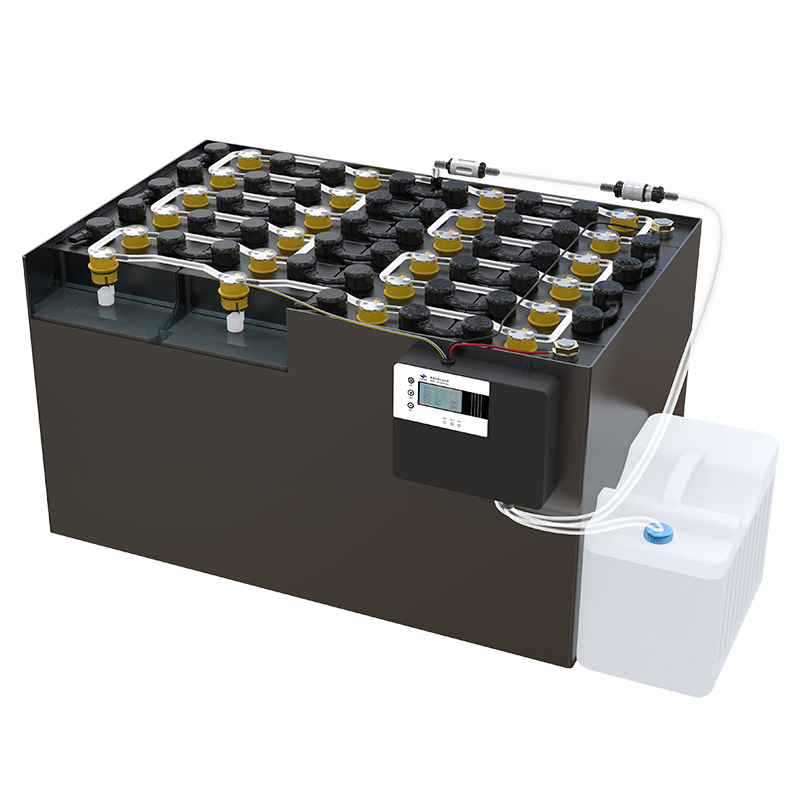

The forklift battery watering system is a patented product independently developed by Hubei Lham. It is an automatic water replenishment device developed for liquid-rich batteries. It can completely replace the manual maintenance of batteries, monitor the water shortage status of the battery in real-time, and automatically replenish water. After the equipment is installed, the electrolyte level can be kept in a healthy state throughout the whole process, ensuring the stability and balance of the electrolyte characteristics of the battery, optimizing the use efficiency of the battery equipment, and prolonging the service life of the battery.

The Hubei Lham forklift automatic water replenishment system retains the advantages of ordinary lead-acid batteries with high stability, strong environmental adaptability, and low price. At the same time, it has a stable service life and great maintenance convenience at a very low cost.

The battery is very important to the electric forklift, and its normal operation is a necessary condition for the efficient operation of the forklift. Adding water to the battery is not as simple as opening the battery filler cap and filling it with water. What kind of water should be added, when to add water, and which situations need to be added are all knowledge that needs to be mastered. Correct and timely replenishment of water can ensure the good operation of the battery and effectively prolong the service life of the battery.