The basic operating functions of forklifts are divided into horizontal handling, stacking/picking, loading/unloading, and picking. According to the operation function to be achieved by the enterprise, it can be preliminarily determined from the models introduced above.In addition, special operation functions will affect the specific configuration of the forklift, such as paper rolls, molten iron, etc., and the forklift needs to be installed with attachments to complete the special functions.

Operating requirements

The operating requirements of the forklift include general requirements such as pallet or cargo specifications, lifting height, working channel width, grade of grade, etc., and also need to consider operating efficiency (different models have different efficiencies), operating habits (such as accustomed to sitting or standing), etc.

Operating Environment

If the goods or warehouse environment that the enterprise needs to transport has environmental protection requirements such as noise or exhaust emissions, it should be considered when selecting models and configurations. If it is in a cold storage or in an environment with explosion-proof requirements, the configuration of the forklift should also be a cold storage type or an explosion-proof type.

Carefully examine the locations that the forklift has to pass through during operation, and think possible problems, such as whether the door height affects the forklift when entering and leaving the warehouse; when entering and exiting the elevator, the impact of the elevator height and load on the forklift; when working upstairs, the floor load Whether the corresponding requirements are met, etc.

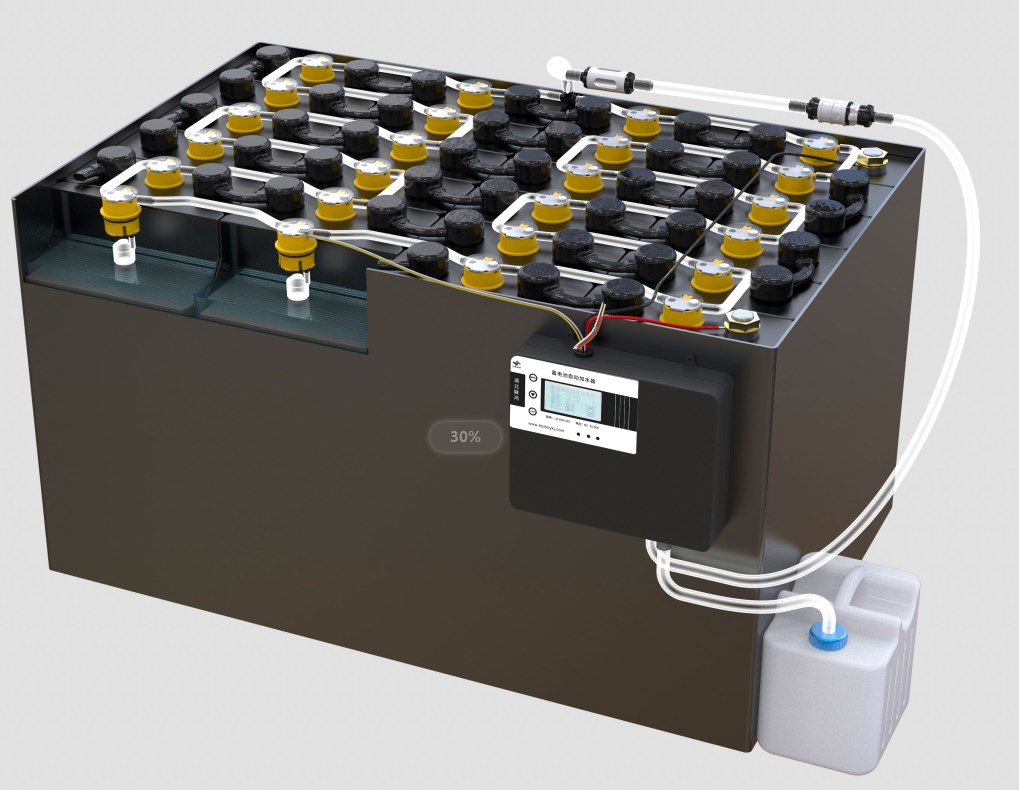

How to prolong electric forklift battery service life? Battery watering Technology is your best choice.

When selecting and determining the configuration, it is necessary to describe the working conditions in detail to the forklift supplier and conduct on-site investigations to ensure that the purchased forklift fully meets the needs of the enterprise. Even if you complete the analysis of the above steps, there may still be several models that can meet the above requirements at the same time. At this point, you need to pay attention to the following aspects:

1.Different models have different work efficiency, so the number of forklifts and drivers required are also different, which will lead to a series of changes in cost. For details, please refer to the discussion on cost in the performance evaluation section of this article.

2.If forklifts operate in the warehouse, the width of the aisle required by different models is different, and the lifting capacity is also different, which will bring about changes in the layout of the warehouse, such as changes in the amount of goods stored.

3.The Changes of models and numbers will have an impact on many aspects such as fleet management.

4.The market ownership of different models is different, and their after-sales support capabilities are also different. For example, the low-position driving three-way stacker forklift and the high-position three-way stacker forklift belong to the series of narrow aisle forklifts, which can be used in very narrow aisles (1.5 ~ 2.0 m) to complete the stacking and pickup.

However, the cab of the former cannot be raised, so the operating field of vision is poor and the work efficiency is low. Because the latter can completely cover the functions of the former, and its performance is more outstanding, the sales of the latter in Europe is 4 to 5 times higher than that of the former, and it is more than 6 times in China.

Therefore, most suppliers focus on the development of high-position driving three-way stacker forklifts, while low-position driving three-way stacker forklifts are only used in the working conditions of small tonnage and low lifting height (generally within 6 meters). When there are few sales in the market, the number of after-sales engineers, the experience of engineers, the level of spare parts inventory and other service capabilities will be relatively weak.