1.How Long Do Forklift Batteries Last?

Forklift batteries don’t last forever. A standard lead-acid forklift battery is good for about 1,500 charging cycles. For a single-shift operation, this works out to about a five-year lifespan (if the battery is properly maintained).To maximize the life of your forklift battery:

Follow the manufacturer’s watering and maintenance recommendations.Have your forklift serviced regularly. Don’t re-charge the battery until it has discharged to 30 percent.

Batteries have a limited number of charging cycles, so you don’t want to waste them on lunch-hour top-offs. Opportunity charging forklift batteries is useful for many operations, but there’s a right way and a wrong way to go about it.

2.How do I know if my forklift battery is bad?

When your forklift battery doesn’t hold a charge like it used to, that’s a sign you may need to replace it soon. That said, if the battery is only a few years old/has fewer than 1,000 charging cycles, you may be able to repair rather than replace it.Here are few more signs your forklift battery is going bad:

a.Corrosion on the battery case.

b.Spilled acid on the exterior.

c.A rotten egg smell.

d.Smoke.

e.Corroded or damaged terminals.

f.Dim or flickering displays.

g.Poor response time.

3.Other factors which most often adversely influence service life are:

a..Abnormally high or low electrolyte temperatures.

- Low Temperature

Available forklift battery power is reduced by low temperature because electrolyte viscosity and resistance is increased and diffusion throughout the pores of the active material is retarded. For example, a fully charged forklift battery (1.275 to 1.295 specific gravity at 77 degrees F.), when its electrolyte temperature is about 32 degrees F., will deliver only 75% of the capacity which would be available at normal room temperature. This drops to 40% at 0 degreee F. The electrolyte could freeze if a discharged forklift battery was exposed to very cold temperatures for several hours.

In addition to the discharge related problems, the charge acceptance of a lead-acid forklift battery is impaired when electrolyte temperatures drop below 60 degrees F. As a result, forklift batteries should always be kept fully charged, especially in cold weather. They should be heated, even during operation or storage, if exposure is severe enough to cause the temperature of the electrolyte to approach 32 degrees F.

- High Temperatures

Although high temperatures of up to 110 degrees F, do not cause a reduction in available capacity, battery operation is adversely effected. Because most chemical reactions are accelerated at high temperatures, the rate of corrosion of the positive grid is increased and the active material is shed more rapidly. Even electrolyte temperatures above 90 degrees F. will cause some reduction in service life and should be avoided whenever possible. Cell temperatures should never be allowed to exceed 110 degrees F.

b.Frequent overdischarging.

c.Failure to add water regularly.

d.Frequent overcharging.

e.Poor, or high, resistance, connections or contacts.

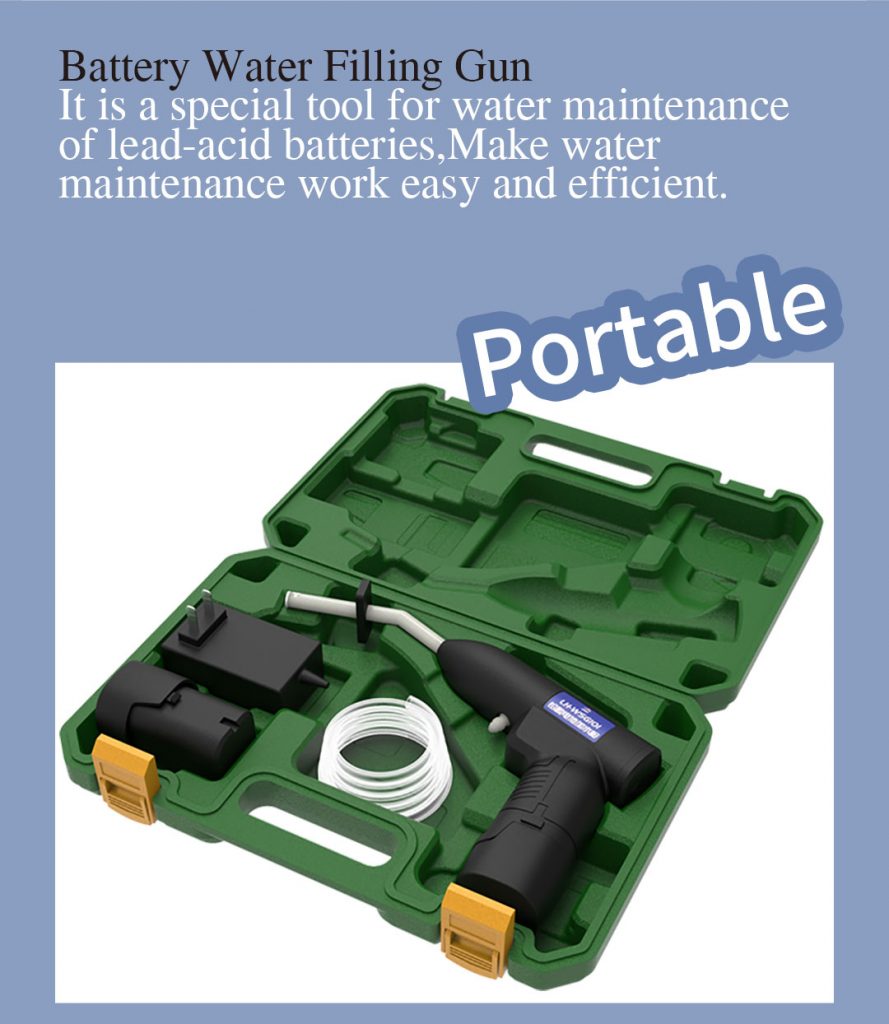

Forklift Battery maintenance tool: Battery Watering Gun and Battery liquid level indicator.

For more information: 86-18007279352.