How many years can a forklift lead-acid battery last? Domestically, it is generally 2-3 years. Whether it is an electric forklift seller or an expert in forklift maintenance, this is generally the case. As far as reality goes, there is nothing wrong with this statement, but they will definitely not tell you some details. Your 2-3 years are not necessarily the same as other people’s 2-3 years.

The scientific calculation method of the service life of a forklift battery is not based on time, but based on the maximum number of discharges that the rechargeable battery can withstand. The current mainstream forklift battery design life is generally 1600 cycles. That is, after 1600 times of charging and discharging, the charging capacity of the battery has dropped to less than 80% of the factory, and the battery is considered to be unable to meet the needs of use and needs to be discarded or replaced.

What tool do you usually use to add water to your forklift batteries?

Have you found the problem?

The frequency and intensity of use of forklifts of different companies or individuals will obviously not be uniform, so how can there be a relatively uniform service life in units of time in this case?

Forklifts in large storage centers or factories will be equipped with backup batteries. When the battery is exhausted, the battery will be replaced directly, and the equipment will not stop. The battery is either working or charging and never stops.

In the case of no interval replacement, a forklift battery performs an average of 1.7 cycles a day, then 1600÷1.7÷365≈2.6 (years)

The service life of the battery under this kind of use intensity is in line with the statement of 2-3 years, but can the forklift batteries of ordinary small businesses or individual users be used to this extent?

If your forklift battery is cycled once a day, then it is 1600÷1÷365≈4.4 (years), that is to say, if it is used in a charge-discharge cycle once a day, it will take at least 4 years to maintain its value.

That is to say: without working overtime, a forklift battery only lasts for 2-3 years, which means that more than 40% of its value is wasted. Taking a 48V forklift battery with a unit price of about 2w as an example, the net loss of each battery is about 8k.

So the question is: how did this gap come about?

The service life of forklift batteries is closely related to daily maintenance.

Manufacturers equipped with a large number of electric forklifts generally have a dedicated maintenance personnel for every 10 vehicles, as well as special charging stations and a variety of professional maintenance equipment, in order to ensure that each forklift and each battery get the best maintenance. The service life can be brought into full play. It’s just that for individual users, if there is no certain number of forklifts to share, the cost of this solution is too high.

So is there any maintenance solution suitable for our individual or small and medium-sized forklift users?

Of course there are. The average service life of forklift batteries in developed foreign countries is only 4-5 years. Their labor costs are high, and forklift batteries are charged and discharged every day. However, employees have a high awareness of battery maintenance, and the development of supporting industries is relatively mature. There are many “black technologies” for battery maintenance to help individuals and small and medium-sized enterprises perform professional maintenance on batteries:

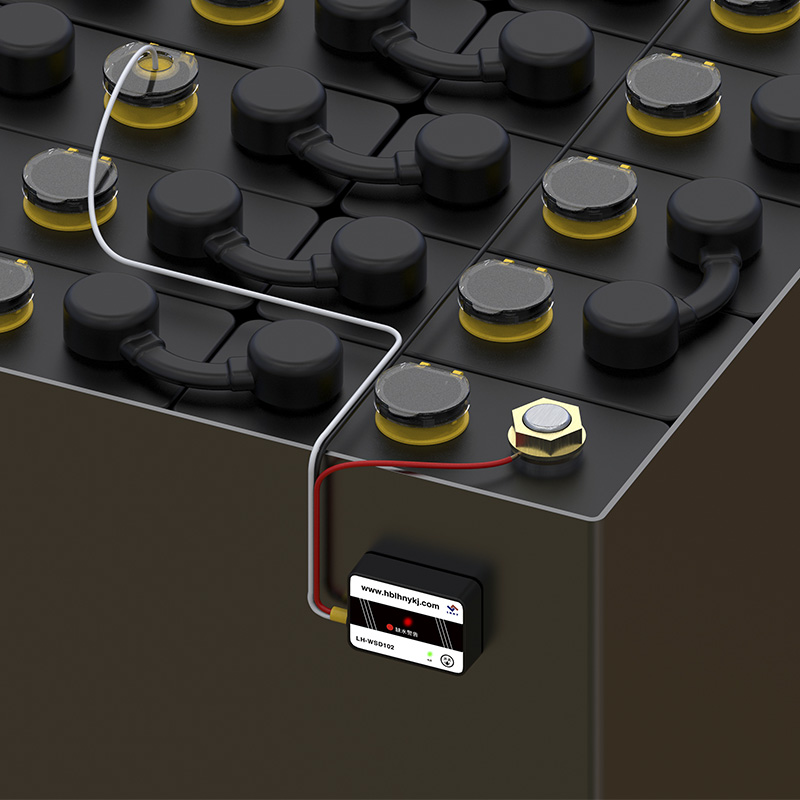

Water shortage alarm (prompt the user to replenish water in time)

Battery water gun (a special watering tool for lead-acid batteries, which can balance the liquid level and automatically stop when it is full of water)