二. Anatomy and Analysis

(3)Observe the status of the pole group, whether there is a lack of separators, whether the bus bar is broken, the connection between the bus bar and the electrode tabs, whether there is chip drop and false welding phenomenon. Observe whether the connection between the pole and the busbar, the pole and the end pole is broken, and the phenomenon of false welding and false welding, and observe whether there is foreign matter in the pole group.

(4)Observe the side of the pole group, whether there is a short circuit at the bottom and whether the separator is in the pole group and whether the edge of the separator is damaged.

( Common fault analysis and treatment method of lead-acid battery >>>>>>>>Click Here)

(5)Observe the electrolyte condition in the battery tank, the deposition of active material, whether there is foreign matter in the tank, and whether the partition plate in the battery tank is cracked, damaged, or communicated between cells.

(6)After completing the above observation, use an iron saw to cut the connection between the pole plate and the bus bar, and check the conditions of the positive plate, the negative plate and the separator piece by piece.

(7)Observe whether the four frames of the positive plate are broken, the surface of the plate, the active material falling off, the corrosion and fracture of the small ribs, and whether the plate is bent or not.

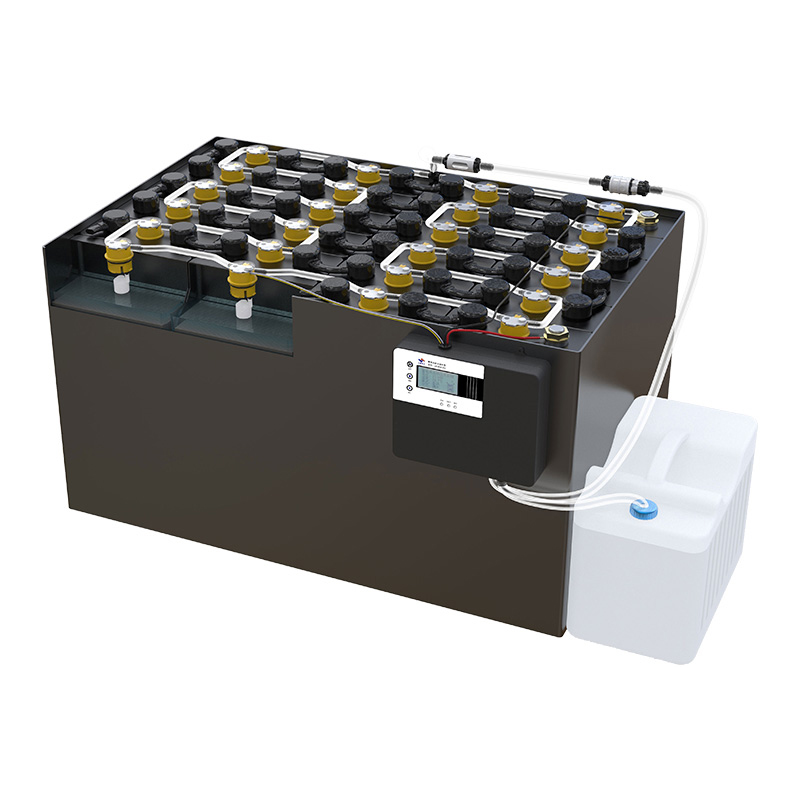

(How to maintain electric forklift battery? You can try the following Battery Water Filler)

(8)For the tubular positive plate, observe whether the wire tube is damaged, whether the lead core is necked, whether the back cover is falling off, whether the bus bar is broken, whether the active material in the tube sinks, and the degree of empty tube.

(9)Observe the surface condition of the negative plate, whether there are signs of sulfation, whether the active material shrinks and hardens, whether there is swelling, accumulation and falling off.

(10)Observe the degree of corrosion of each separator, whether there is damage, breakage, corner drop, or perforation. When observing the separator, the separator should be washed with water and carefully observed.

(11)After analyzing and recording the battery anatomy observation, record the observation results, analyze the reasons that affect the battery performance and cause the termination of the test, and propose the battery anatomy analysis.

| Common fault analysis and treatment method of lead-acid battery |

| Common error | Unpleasant sight | Cause of failure | Troubleshooting |

| Insufficient battery charge | 1. Low static voltage 2. The density is low, and the specified requirements cannot be met after charging 3. Short working hours 4. When working, the meter shows that the capacity drops rapidly | 1. Charger voltage and current settings are too low 2. Insufficient initial charge 3. Charger failure | 1. Adjust and overhaul the charger 2. Supplementary battery charging 3. In serious cases, replace the battery with a new one |

| Battery overcharged | 1. The color of the injection lid basket turns yellow and red 2. shell deformation 3. Separator carbonization and deformation 4. Positive electrode corrosion, fracture 5. The pole rubber sleeve rises, ages and cracks 6. Replenish water frequently, the electrolyte is cloudy when charging 7. The active material of the plate falls off evenly 8. The positive plate bursts the tube | 1. Charger voltage, current set too high 2. Charging time is too long 3. frequent charging 4. Charger failure | 1. Adjust and overhaul the charger 2. Adjust the charging system 3. In serious cases, replace the battery with a new one |

| Battery over- discharge | 1. Low battery voltage 2. Low electrolyte density after charging 3. Positive and negative plates are bent and broken | 1. The battery is insufficiently charged and continues to be used 2. Battery pack short circuit 3. Small current for long time discharge | 1. recharge 2. overhaul the vehicle 3. In serious cases, replace the battery with a new one |

| Battery short circuit | 1. The static voltage is below 2V 2. Electrolyte density is too low 3. High temperature when charging 4. Short working hours | 1. Plate bending deformation short circuit 2. Spacer missing or broken during assembly 3. The positive active material falls off and the bottom is short-circuited | Need to replace new battery |

| Open circuit | 1. When the external load path is connected, the voltage is abnormal and unstable 2. Current cannot be input during charging | 1. Poor welding of pole or plate assembly 2. External short circuit 3. High current discharge 4. Poor connection or disconnection 5. Plate corrosion | 1. Battery needs repair 2. Replace batteries if necessary |

| Improper addition of electrolyte to battery | When the density is high: 1. Electrolyte density after charging ≥1.300g/cm3 2. High battery static voltage 3. The initial capacity is good, and the capacity decreases after a period of use 4. The electrolyte is cloudy When the density is low 1. The electrolyte density is lower than the specified value after charging 2. low battery capacity, Impure dosing 1. low battery capacity 2. The electrolyte is cloudy, abnormal in color and odor 3. Serious battery self-discharge | 1. The density of the initial solution is too high or too low 2. The liquid level is lowered and the rehydration is wrong. Instead of adding pure water as required, dilute acid is added by mistake. 3, The initial addition solution is impure (contains impurities) | 1. battery electrolyte replacement 2. In severe cases, a new battery needs to be replaced |

| Plate Sulfation | 1. Reduced capacity during normal discharge 2. Density drops below normal 3. Rapid voltage drop during discharge 4. Start charging voltage high 5. Bubbles are formed early when charging 6. Coarse crystals of PbSO4 | 1. Insufficient initial charge 2. In the discharge state, the storage time is too long 3. Long-term insufficient charging 4. Electrolyte density is too high 5. The liquid level is too low, and the upper part of the plate is exposed to 6. Impure electrolyte 7. Internal short circuit | 1. overcharge method 2. Repeated charging method 3. hydrotherapy |

| Excessive shedding of active substances | 1. A gray-brown substance rises from the bottom when charging 2. Reduced battery capacity | 1. Brown precipitation is due to excessive charging current 2. White precipitation is due to overdischarge 3. Impure battery electrolyte | 1. clean up sediment 2. Adjust density 3. Replace batteries if necessary |

| Battery reverse | 1. Voltage is negative 2. After charging, the electrolyte density is below 1.20 g/cm3 3. Positive and negative poles and plates have opposite colors | The positive and negative poles are connected incorrectly when charging | 1. Reverse chargeable 2. In severe cases, a new battery needs to be replaced |

| Battery leakage | 1. The injection port leaks at night 2. Leakage at groove and cover seal 3. exudate 4. There are bump marks on the outside of the tank | 1. Poor heat sealing of grooves and covers 2. Pole rubber ring problem 3. cracked sealant 4. Neglect to be impacted by external force during use | 1. repair 2. Replace batteries if necessary |

Battery Watering System Video

Whatsapp: +86-18007279352; Email: lhny998@gmail.com