一.The reason that can’t be charged

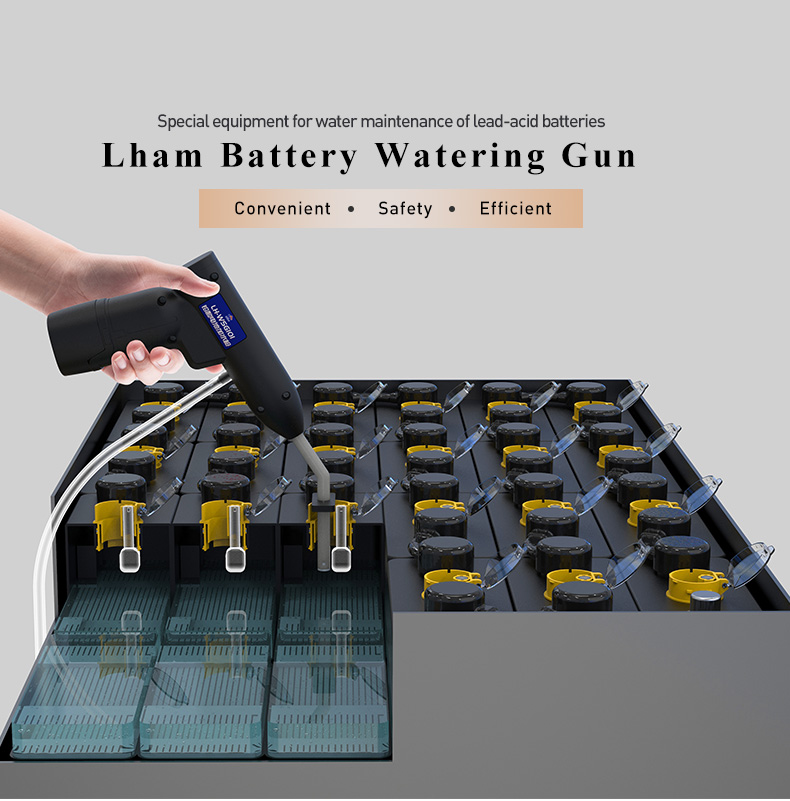

1.The battery water level is abnormal

When the forklift driver encounters such problems, first check whether the water level in the battery is normal. If the water level is low, add an appropriate amount of distilled water firstly.

2.There is irreversible sulfation of the battery plate

The irreversible sulfation of the electrode plate can be determined by measuring the change of its terminal voltage by charging and discharging. When charging, the voltage of the battery rises very fast, and the voltage of some cells is very high, which exceeds the normal value by a lot; when discharging, the voltage drops very fast, and the battery has no or very little power. When the above situation occurs, it can be judged that the battery has irreversible sulfation.

3.Self-discharge phenomenon

After the electric forklift has been idle for a period of time, it has not been used, nor has the electric forklift been charged. When it is used, the battery of the electric forklift is found to be insufficient and the electric forklift cannot be used normally. This is the so-called “starved to death” of the electric forklift battery. Professional The argument is that the battery is out of power, because lead-acid batteries have the phenomenon of self-discharge. After a long time without charging, the power is exhausted and it enters the feeding state, which causes the protection circuit in the battery to act.

二. The maintenance and care

Then, in accordance with the daily maintenance items, the following first-level maintenance work can be added.

1. Check whether the thermostat works normally.

2. Check whether the shifting of the transmission is normal.

3. Check the tightness of the fan belt.

4. Check whether the filter screen of the oil inlet of the diesel tank is blocked or damaged, and clean or replace the filter screen.

5. Check and adjust the valve clearance.

6. Check and adjust the gap between the brake pads of the hand and foot brakes and the brake drum.

7. Check whether the generator and starter motor are securely installed, and whether the terminals are clean and firm, and check whether the carbon brushes and commutators are worn or not.