I have done the forklift battery maintenance work for many years. Because of the work, I am often asked the question about forklift battery maintenance by people around me. Among them, the most controversial issue is: when does the forklift battery need to be added water? Here is a unified answer to this question.

一. The effect of charging on the battery level:

1.The liquid level in the battery changes before and after the battery is charged, which is also an important basis for us to regulate the time to add the water to the battery. Generally speaking, the liquid level in the battery when it is fully charged will be 1 to 2 cm higher than the liquid level in the battery after a deep discharge. Therefore, we must avoid adding too much water before charging the battery (here, only distilled water or deionized water added in daily maintenance), which will cause the electrolyte in the battery to overflow and lose the sulfuric acid solution during charging. That’s why we say adding water is best after the battery is fully charged.

2.At the end of the lead-acid battery charging process, the temperature of the electrolyte rises and the flow accelerates, and even a slight boiling phenomenon occurs. As we all know, the battery electrolyte is a sulfuric acid solution. Adding distilled water directly to the sulfuric acid solution will cause liquid stratification. It takes a long time to mix the acid solution and distilled water. Using the electrolyte flow and slight boiling at the end of the battery charging can help the electrolyte and the newly injected distilled water to mix, which is the theoretical basis for adding water during battery charging.

3.When the water shortage of the lead-acid battery is serious, the battery plate has been exposed to the air in a large area, and the charging process will accelerate the sulfation of the exposed plate. In this way, even if water is added for maintenance later, some plates will not participate in the charge-discharge reaction due to sulfation, resulting in a decrease in battery capacity. This is the theoretical basis for adding water before the battery is charged.

二.When is it better to add water to the forklift battery:

1.In the case of timely maintenance of battery watering, we generally only require water maintenance after the battery is fully charged. In this way, there is not much distilled water to be filled each time, and it has little effect if it is not fully mixed with the electrolyte in time.

2.When the battery has not been filled with water for a long time, the liquid level of the battery has dropped below the lead grid of the battery. It is best to add some water before charging so that the electrolyte passes the lead grid. Fill up the liquid level after charging is completed, and if necessary, perform equalization charging after replenishing water to repair part of the plate sulfation caused by water shortage.

3.Water maintenance at the end of battery charging can be considered as the most scientific maintenance method. However, in actual operation, there are certain safety risks, and the water addition operation needs to be carried out twice, which will consume a lot of time, so this method is generally not used.

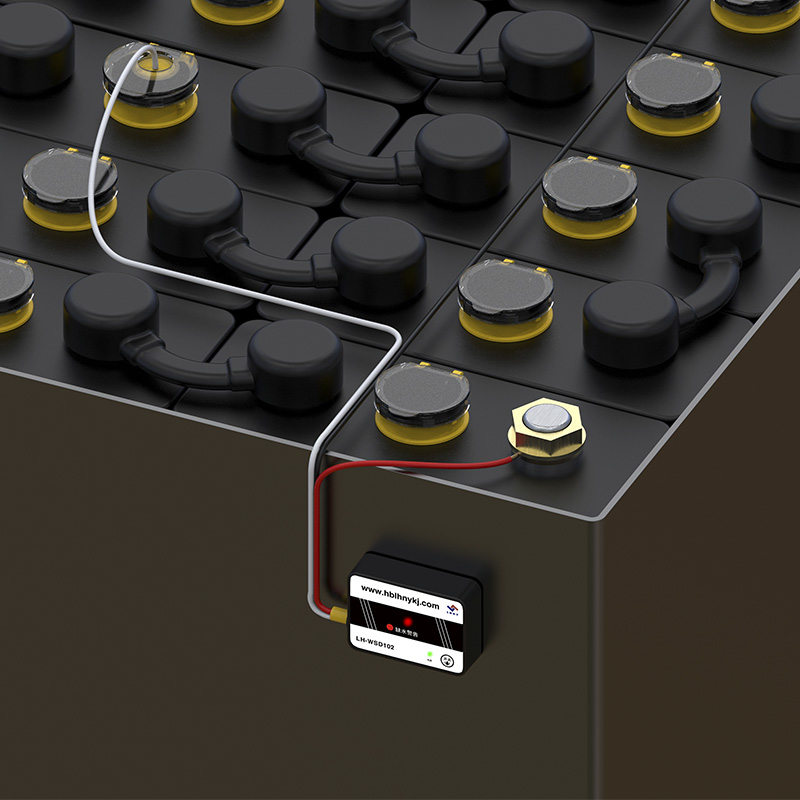

Of course, for battery water maintenance, now we have better solutions, such as battery water shortage alarms, battery water tools, and automatic battery water filling systems, which are our main products of Hubei Lham . All of them are special tools for battery maintenance developed by Hubei Lham Energy according to the pain points of forklift batteries in the market.